Ultrasound-Assisted Dyeing for Natural Dyes

Ultrasound-assisted dyeing is transforming how we use natural dyes in textiles. It uses sound waves to create microscopic bubbles that help dye molecules penetrate fabric fibers more efficiently. This process improves color strength, reduces water and energy usage, and shortens dyeing time compared to older methods. Here’s what you need to know:

- Efficiency Boost: Increases dye uptake by up to 120% and enhances color strength by 25.6%.

- Resource Savings: Cuts water use by 30%, energy consumption by 50%, and dyeing time by over 60%.

- Eco-Friendly: Reduces chemical inputs, CO₂ emissions, and wastewater output.

- Versatility: Works on natural fibers like cotton, silk, wool, and jute.

Ultrasound technology is already being adopted by brands to lower costs and improve dye quality while reducing environmental harm. This method offers a practical solution for ethical fashion brands aiming to create vibrant, long-lasting colors with minimal impact.

How Ultrasound-Assisted Dyeing Works

The Science Behind Ultrasound Dyeing

Ultrasound technology transforms the dyeing process by leveraging the power of cavitation - tiny bubbles created by ultrasonic waves that collapse almost instantly. This action forms microscopic channels on the fiber's surface, allowing dye molecules to penetrate deeply. Think of it as a tiny jackhammer breaking down barriers for better dye absorption. Beyond that, ultrasound disperses dye molecules evenly and releases trapped gas, improving dye uptake. The process also generates micro-currents, known as acoustic streaming, which speed up the bonding between dye and fiber. As Hielscher Ultrasonics explains:

"Ultrasonically assisted dyeing of fibers and fabrics improves the penetration of the dye into the fiber pores and increases colour strength and colour fastness significantly." [5]

A 2016 study by Tissera et al. highlighted the impact of ultrasound in practice. Using mild sonication (0.7 W/cm²) with the UP400St ultrasonic processor at around 86°F (30°C), they achieved a whopping 230% higher color strength compared to traditional heat-based methods. [5] This demonstrates how ultrasound not only enhances molecular interactions but also cuts down on resource use.

Resource Savings with Ultrasound Dyeing

The resource efficiency of ultrasound-assisted dyeing is equally impressive. In cotton reactive dyeing, ultrasound improves dye uptake, boosts color strength, and reduces the liquor ratio to 6:1. This translates to over 60% shorter dyeing times and a 50% drop in alkali consumption. These savings are partly due to the elimination of traditional scouring and bleaching pretreatments. Ultrasound also prevents dye particles from clumping together, breaks larger particles into smaller ones for better dispersion, and removes air pockets at fiber cross-points. [7]

Better Dye Absorption on Natural Fibers

Ultrasound proves its versatility by working effectively on natural fibers like cotton, silk, wool, and jute. It promotes fiber swelling and enhances the transfer of dye compounds into the fibers. For plant-based dyes, ultrasound goes a step further, breaking down the cellular structure of both the dye source and fabric, which speeds up solvent and dye penetration. For example, research using Bixa orellana seeds showed that an ultrasonic water bath at approximately 140°F (60°C) for 40 minutes (without using mordants) successfully dyed cotton, silk, and leather. The color values recorded were L*, a*, b* of 80.95, 4.52, 75.35 for cotton; 88.65, –1.35, 62.85 for silk; and 79.55, 15.35, 66.45 for leather. [9]

Further studies with Dillenia indica leaf dyes demonstrated the dual benefits of ultrasound for both dye extraction and application. The method achieved excellent color fastness against washing, rubbing, and light exposure. Research by Udrescu et al. found that the best results occurred at about 176°F (80°C) with a 90% bath exhaustion rate. Washed yarns maintained fastness ratings of 4–5 on standard scales. [8] As Mason et al. observed:

"The primary mechanism of ultrasonic extraction was the amplification of mass transfer via ultrasound and the fast access of solvent to plant cell components." [8]

This ability to fine-tune the process makes ultrasound-assisted dyeing a reliable choice for achieving consistent, high-quality results in sustainable fashion production.

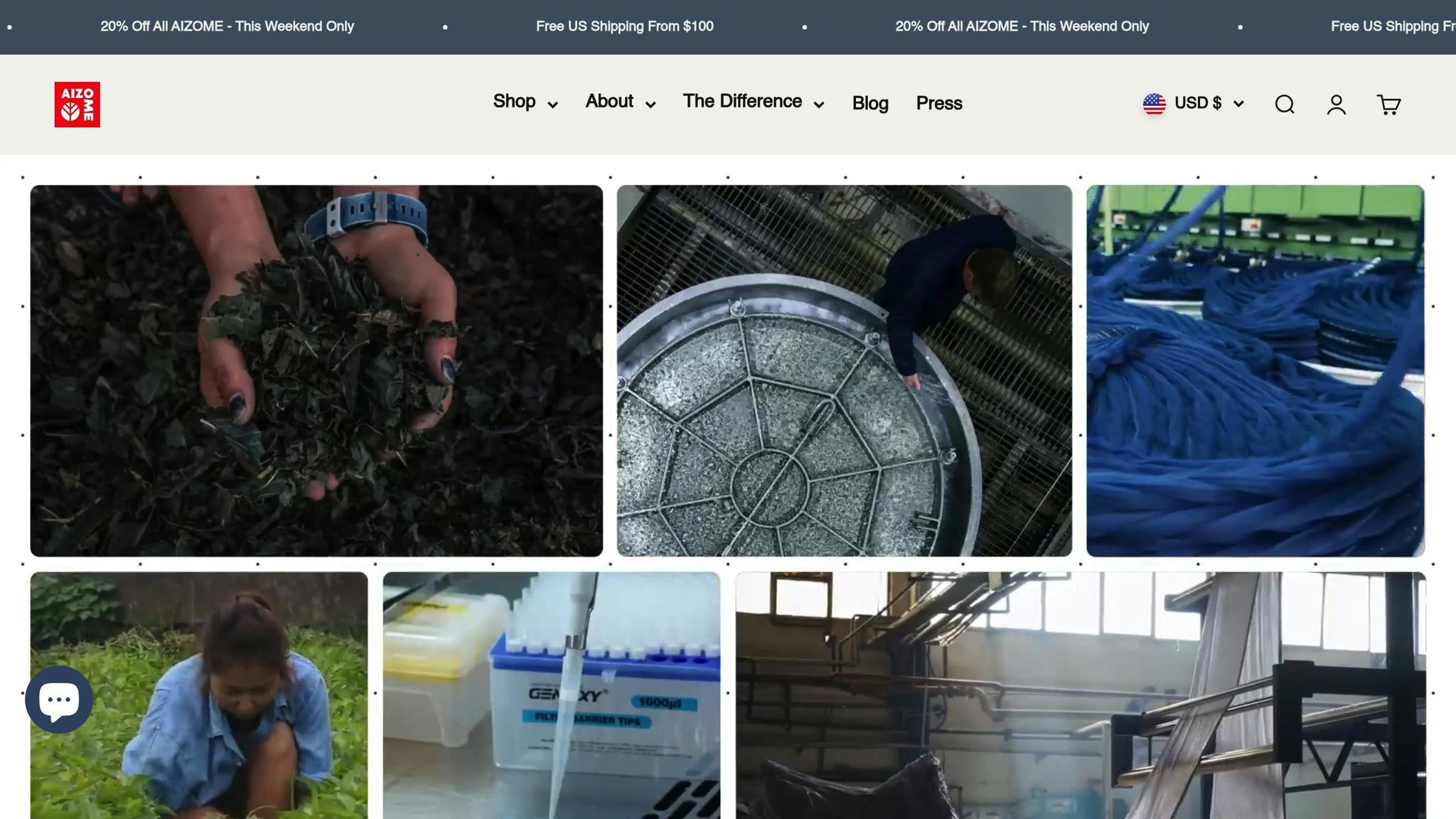

Wastecare™ (Case Study) - AIZOME

Ultrasound vs Standard Dyeing Methods

In the world of sustainable fashion, minimizing resource use and ensuring fabric durability are key priorities.

Resource Use Comparison

Ultrasound-assisted dyeing offers a significant reduction in resource consumption compared to traditional methods. To put it into perspective, conventional dyeing processes require 50-300 liters of water for every 2.2 pounds (1 kg) of fiber, making it one of the most water-intensive steps in textile manufacturing. In fact, wet processing - which includes dyeing, printing, and finishing - accounts for a staggering 72% of the textile industry's total water demand [10].

Ultrasound technology significantly eases this burden. A study published in the Journal of Cleaner Production in December 2022 by Xueyan Bian and her team highlighted the advantages of ultrasonic energy in cotton dyeing. The research revealed that liquor ratios could be reduced to 6:1, while dyeing time and alkali consumption decreased by over 60% and 50%, respectively [7].

Additionally, ultrasound operates at lower temperatures, ranging from 86–104°F (30–40°C), cutting energy use by up to 40% [10]. Beyond water and energy savings, ultrasound improves dye extraction efficiency and reduces wastewater output, making it a cleaner alternative to conventional methods.

These resource savings also pave the way for better color performance and fabric longevity.

Better Color Results and Durability

Ultrasound-assisted dyeing doesn't just save resources - it also enhances color quality. This method achieves dye exhaustion rates exceeding 99%, delivering higher color strength (K/S values) compared to traditional techniques that rely on dispersing agents [11].

Fabrics dyed with ultrasound maintain their vibrant hues even after repeated washing and wear. Studies show significant improvements in wash, rubbing, and perspiration fastness [5]. Moreover, the gentle nature of ultrasonic treatment preserves the fiber's surface and structure, ensuring both deeper dye penetration and long-lasting quality.

| Advantages | Performance Benefits | Quality Improvements |

|---|---|---|

| Enhanced dye penetration into fibers | Higher color strength | Improved color consistency |

| Faster dyeing process | Better dye uptake and strength | Superior wash, rubbing, and perspiration fastness |

| Suitable for various fabrics (wool, silk, polyamide) | Reduced processing costs | Eco-friendly process |

| Simple and safe operation |

Another standout feature is the uniformity of color distribution. Ultrasound breaks up and evenly disperses dye molecules, allowing them to penetrate fabric fibers more thoroughly. This results in consistent, even coloration - avoiding the blotchy or uneven finishes often associated with traditional dyeing methods.

Noman Habib and his team emphasized the eco-friendly benefits of ultrasound in their research:

"Ultrasonic treatment, a procedure that is harmless for the environment, has only served to increase the color strength of dye on wool fabric, and the addition of bio-mordants has made the process more sustainable." [4]

For brands like dorsaLi, which focus on delivering high-quality products with minimal environmental impact, ultrasound-assisted dyeing offers the perfect solution. It produces vivid, durable colors while significantly lowering the environmental footprint - a combination that conventional dyeing methods simply can't achieve.

sbb-itb-9137a7f

Uses in Fashion Production

The fashion world is turning to ultrasound-assisted dyeing as a smart way to make production more sustainable. This cutting-edge technology is proving itself in practical applications across the industry.

Real Examples of Ultrasound Dyeing in Fashion

Take Candiani Denim, for example. Back in Spring 2022, this Italian denim maker introduced "Sound Dye", an ultrasound-based process that transformed how they rinse yarn. The results? A dramatic reduction in water usage - from 7 liters per linear meter in traditional methods to just 2 liters. With an annual production of 20 million linear meters, this translates to saving a staggering 52.3 million liters of water every year[12].

"We believe that innovation is a key driver for sustainability. We always try to challenge the status quo by searching for and developing new and measurable solutions to reduce our environmental impact." – Candiani Denim[12]

Another standout is DyeCoo Textile Systems, which has pushed the boundaries of supercritical CO₂ dyeing by integrating ultrasonic technology. Their systems now handle up to 800,000 kilograms of polyester textiles annually, saving 32 million liters of water and 160,000 kilograms of chemicals, all while recovering 95% of the CO₂ used[6]. Even global brands like Adidas have embraced this method, proving its scalability.

Ultrasound dyeing isn't just about efficiency - it also reduces water usage by nearly 30% compared to traditional techniques. These real-world examples highlight how this approach can benefit not only large-scale operations but also smaller, ethically driven brands.

Benefits for Handcrafted Fashion Brands

Handcrafted brands, like dorsaLi, are reaping the rewards of ultrasound dyeing. Its lower water and energy requirements help preserve natural fibers while ensuring vibrant, long-lasting colors. Considering that dyeing and finishing account for 36% of the textile supply chain's climate impact[1], and that dyeing one kilogram of cotton typically consumes around 125 liters of water[1], ultrasound-assisted dyeing offers a more sustainable alternative.

The process is particularly effective with natural fibers like wool, silk, and cotton - materials often favored by handcrafted fashion brands. By using ultrasound frequencies (20 kHz–500 MHz), cavitation bubbles form, which enhance dye penetration. This results in more even coloring and allows dyeing to take place at lower temperatures, cutting energy costs - a crucial advantage for brands working with limited budgets.

This technology not only reduces environmental impact but also aligns with the high standards of sustainable craftsmanship. It supports in-house production, giving brands greater control over their processes while achieving professional-grade results.

Growth Potential for Eco-Friendly Dyeing

The sustainable textiles market is on the rise. Valued at $5.8 billion in 2019, it’s projected to grow to $13.4 billion by 2027, with a compound annual growth rate (CAGR) of 12.2%[6]. This growth is fueled by renewed interest in natural dyes and advancements in low-water and waterless dyeing methods, creating opportunities for innovative approaches like ultrasound-assisted dyeing.

While techniques such as ultrasound and foam dyeing show promise, scaling them up remains a challenge due to limited industrial data on resource savings[3][6]. That said, foam dyeing alone can cut water use by up to 95% compared to traditional methods[6].

Ultimately, reducing resource consumption not only lowers costs but also improves dye quality, minimizing waste and returns. For brands committed to sustainability and craftsmanship, ultrasound-assisted dyeing offers a clear path to lowering their environmental footprint without compromising product excellence. It’s a forward-thinking option for those looking to balance eco-consciousness with high-quality production.

Key Points and Takeaways

Main Benefits of Ultrasound-Assisted Dyeing

Ultrasound-assisted dyeing is changing the game for textile production, offering a more efficient and resource-conscious approach. This method not only saves water and energy but also improves dye uptake, enhances color strength, shortens processing times, and reduces the need for chemicals compared to traditional dyeing techniques[2].

For instance, the process enables a liquor ratio as low as 6:1[2], significantly reducing water consumption. In reactive cotton dyeing, it slashes salt usage by about 60% while maintaining - or even improving - color yield and fastness[13]. When it comes to natural dyes like madder, Reseda, and pomegranate peel, ultrasound-assisted extraction achieves efficiencies of 23%, 33%, and 29%, respectively[8].

This technology works well across a variety of natural fibers, including wool, silk, and cotton. For example, in wool dyeing with Amba Haldi, ultrasonic treatment at 167°F (75°C) for 45 minutes delivered excellent color depth, showcasing its adaptability to different fiber types[4].

Impact on Ethical Fashion Brands

Ethical fashion brands stand to gain significantly from ultrasound-assisted dyeing. By reducing energy consumption to as low as 70% of what traditional water-based dyeing requires[2], this method is particularly appealing to smaller brands with tighter budgets. It also works seamlessly with unscoured and unbleached cotton, eliminating the need for energy-intensive pretreatment steps that are common in conventional processes[2].

The technique doesn't just save resources - it also enhances the quality of the final product. Improved color fastness and deeper penetration ensure garments retain their vibrant look over time. This durability aligns perfectly with the goals of sustainable brands like dorsaLi, which focus on creating timeless, high-quality pieces that prioritize longevity over fast fashion trends. Ultrasound-assisted dyeing supports this commitment to craftsmanship and sustainability, making it a valuable tool for brands aiming to redefine responsible fashion.

FAQs

What are the sustainability benefits of using ultrasound-assisted dyeing with natural dyes in fashion?

Ultrasound-assisted dyeing brings a refreshing approach to sustainability in the fashion industry. By boosting the absorption of natural dyes, this method cuts down on the need for extra dye and water, significantly reducing resource use. It also slashes energy consumption and either minimizes or completely removes the need for harmful chemicals, offering a cleaner alternative to traditional dyeing techniques.

What’s more, this process doesn’t just benefit the environment - it enhances the final product too. The improved efficiency of ultrasound-assisted dyeing produces rich, long-lasting colors while leaving a smaller environmental footprint. As the demand for greener practices in textile production grows, this method helps deliver high-quality fashion with an eco-conscious twist.

How does ultrasound technology improve the dyeing process for natural fibers like cotton and silk?

Ultrasound technology plays a key role in improving the dyeing process for natural fibers. It boosts color intensity and ensures uniform dye coverage, leading to more vibrant and consistent results. What’s more, it speeds up the dye absorption process, making the entire procedure faster and less wasteful.

Another major advantage is its eco-conscious approach. This technique uses less energy and water, all while protecting delicate fabrics like cotton and silk. The outcome? A high-quality finish that meets today’s demand for environmentally responsible and ethically sound practices.

Is ultrasound-assisted dyeing a sustainable option for large-scale textile production?

Ultrasound-assisted dyeing offers a greener alternative for large-scale textile production. Studies indicate it cuts down on energy, water, and chemical usage while boosting dyeing efficiency. This method not only enhances the brightness of natural dyes but also reduces the environmental footprint, presenting a more sustainable choice for the textile industry.

Commentaires